Locations

Serving Customers For Over 55 Years

Arena’s Kinder and Baywood Plants are managed by a team of experienced professionals with over 250 years of combined experience in the aggregate mining and processing industry. We provide best-in-class aggregates and filter media including sand, gravel and anthracite filter media, specialty concrete blending sand, swimming pool pebble aggregates, silica sands, masonry and concrete sands, and frac sand proppants nationwide.

Kinder Plant

Operating since 1965, the Kinder Plant’s two mining facilities sit on 1,000 acres of 80 million tons of proven and recoverable sand reserves. Throughout its 55-year existence, the Kinder Plant has produced many trusted product lines including various grades of silica sands, masonry, and concrete sands, and frac sand proppants to meet customer needs.

Baywood Plant

Operating since 1989, the Baywood plant was founded to mine, process, package, and supply filter media to regional chemical plants, refineries, and water treatment facilities. With an annual production capacity of nearly 1 million tons, the Baywood Plant has offered its customers best-in-class aggregates and filter media including sand, gravel and anthracite filter media, specialty concrete blending sand, swimming pool pebble aggregates, and customized frac sand proppants.

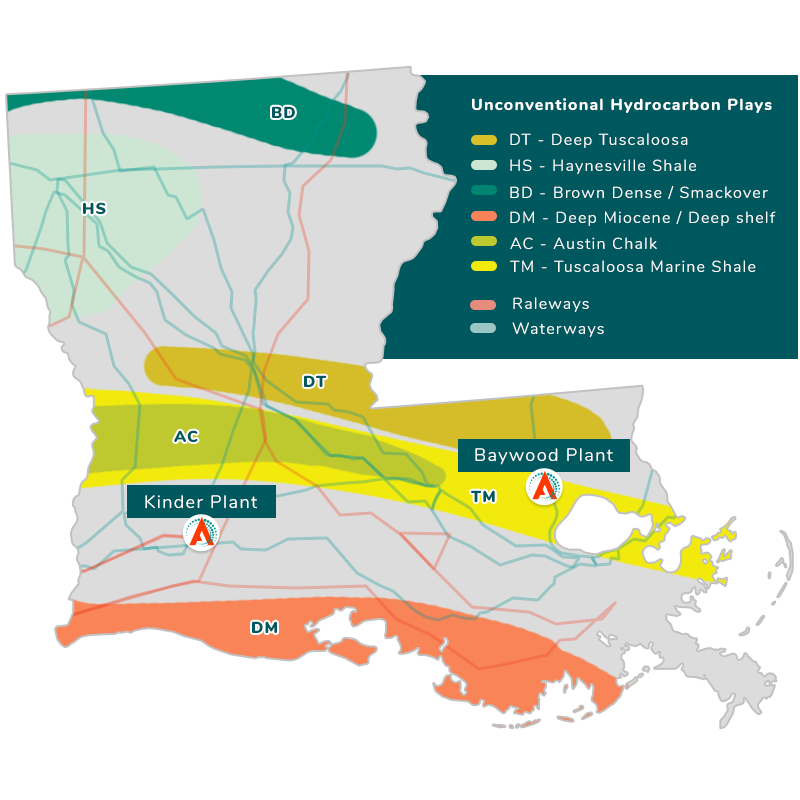

Arena is ideally positioned as the low-cost producer and shipper of frac sand proppants by bulk truck-load to unconventional hydrocarbon plays in Louisiana and East Texas. Additionally, the Kinder Plant’s energy and non-energy products can be shipped nationwide by rail from nearby trans-load facilities in Lacassine, LA (26 miles), and Lake Charles, LA (42 miles), and internationally via the Port of Lake Charles (39 miles). Material from the Baywood Plant can be shipped nationwide, by rail, from a nearby trans-load facility in Port Allen, LA (31 miles), by barge via the Mississippi River (31 miles), and internationally from the Port of New Orleans (105 miles).